Bespoke vs Made-to-Measure: What's the Real Difference?

Understanding the true difference between bespoke and made-to-measure tailoring. Why construction method matters more than you think.

Bespoke vs Made-to-Measure: What

The terms “custom” and “hand-tailored” get thrown around loosely by many clothing companies. This creates a blur that often leads to disappointed professionals who expected a unique masterpiece and received a slightly adjusted standard suit.

You know how frustrating it is to pay a premium for a service, only to realize later that you didn’t get what you thought you were buying?

From our experience, the distinction between these two methods is not just about price. It is the difference between a garment that merely fits your size and one that fits your posture, lifestyle, and professional image.

Let’s break down the data on construction, costs, and longevity, and then explore which option actually delivers the best return on your investment.

Made-to-Measure: Adjusting a Template

Made-to-measure (MTM) begins with a pre-existing “block pattern,” which is a standardized template designed for an average body type. Manufacturers use your measurements to modify this base pattern within set limits.

Think of it like buying a spec home where you can move a few walls and choose the finishes. The foundation and footprint are already poured, but you can adjust the room sizes to better suit your needs.

We find that MTM works best for clients who fall within standard sizing parameters but struggle with one or two specific areas, like sleeve length or waist size.

The Limits of Technology

Most MTM companies use Computer-Aided Design (CAD) software to stretch or shrink the digital pattern. While efficient, this technology has hard limits.

- The “Tolerance” Factor: If your shoulder slope drops more than the software’s pre-set tolerance (often around 1 inch), the system cannot compensate fully.

- Symmetry Assumptions: These systems often assume your left and right sides are symmetrical.

- 2D vs 3D: MTM relies on two-dimensional measurements (length and width) rather than the three-dimensional reality of your body shape.

For many men, MTM offers a significant upgrade over ready-to-wear options.

- Better fit consistency: A 2024 survey of custom clothiers showed MTM achieves a 90% fit success rate for men with standard drops (the difference between chest and waist size).

- Efficiency: The process typically takes 3 to 6 weeks, making it ideal for upcoming events.

- Cost-effectiveness: Prices in California generally range from $800 to $2,500, offering a middle ground for budget-conscious professionals.

However, if you have a “forward-leaning” posture from years of desk work, MTM adjustments often fail to eliminate the collar gap that appears behind your neck.

Bespoke: Built From Scratch

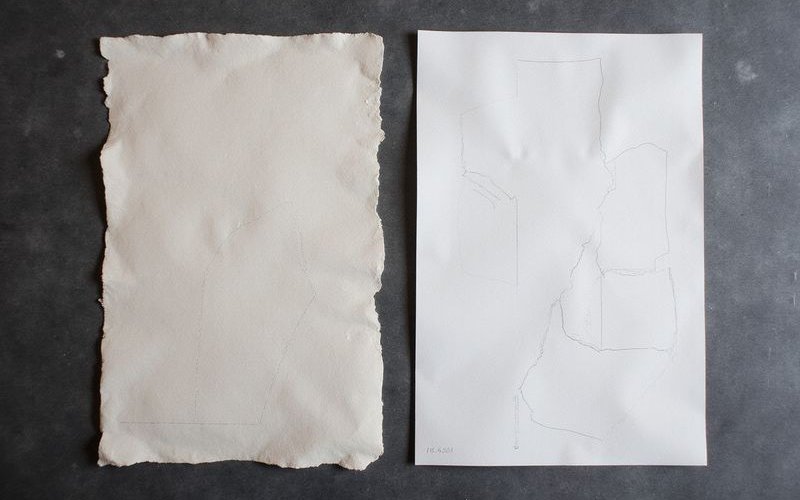

True custom tailoring takes a fundamentally different engineering approach. Instead of modifying a file, a cutter drafts a unique paper pattern specifically for your body from a blank sheet.

This method uses “rock of eye” estimation—an old artisan term for training the eye to see the body’s actual geography—alongside more than 30 precise measurements.

Addressing Structural Nuances

Our team recommends this route for clients who need to accommodate specific physical traits that standard blocks cannot handle.

- Shoulder Slope: We can construct one shoulder pad slightly thinner than the other to level out your silhouette invisibly.

- Postural Alignment: The pattern accounts for the curvature of your spine and the natural resting position of your arms.

- Prominent Seat: A custom cutter drafts the back panels with extra fabric allowance in specific curves to prevent the vents from flaring open.

The garment is constructed almost entirely by hand. This labor-intensive process typically requires 50 to 80 hours of skilled work per suit.

The Construction Difference

The internal engineering of the jacket is where the quality gap widens most.

Made-to-Measure suits are frequently factory-produced. To keep costs down, many use “fusing”—a heat-activated glue—to attach the interlining to the wool. While this looks crisp initially, repeated dry cleaning can cause the glue to degrade, leading to the dreaded “bubbling” effect on the chest.

Bespoke commissions almost always utilize a “full floating canvas.” This internal layer is made from natural horsehair and camel hair.

Why Hand-Padding Matters

An artisan hand-stitches this canvas to the fabric using thousands of tiny, loose stitches.

- Moldability: The canvas floats between the fabric layers and actually molds to your chest shape over time with body heat.

- Breathability: Without a layer of glue blocking airflow, the jacket regulates temperature more effectively.

- Durability: A hand-finished lapel has a natural “roll” that machine pressing cannot replicate, and it retains its shape for decades.

The Fitting Process

The journey from purchase to final product highlights the difference in service levels.

MTM usually involves a single measurement session. Your data is entered into a system, and the finished suit arrives weeks later. If it doesn’t fit perfectly, alterations are done retroactively.

Bespoke requires a series of “baste” fittings that allow the tailor to sculpt the fabric on your body.

- The Skeleton Baste: You try on a scrap version of the jacket held together with white basting thread. This allows the tailor to correct the balance and drape before the expensive fabric is cut.

- The Forward Fitting: The actual fabric is used, but the internal structure is still accessible for fine-tuning.

- The “Finishing” Check: A final review ensures the button stance and hem lengths are visually perfect relative to your shoes and shirt cuffs.

These sessions are not just about checking the size. They are collaborative meetings where we adjust the “attitude” of the suit to match your personal preference for comfort versus structure.

Quick Comparison: By the Numbers

We find that seeing the data side-by-side helps clarify the value proposition.

| Feature | Made-to-Measure (MTM) | True Custom / Bespoke |

|---|---|---|

| Foundation | Standard Block Pattern | Unique Paper Pattern |

| Avg. Timeframe | 3 - 6 Weeks | 8 - 12 Weeks |

| Fittings | 1 (plus final alteration) | 3+ (Baste stages) |

| Typical Cost (CA) | $900 - $3,000 | $3,500 - $6,000+ |

| Lifespan | 3 - 7 Years | 15 - 20+ Years |

| Customization | Visual details (buttons, lining) | Structural & Visual (lapel width, rise) |

When MTM Makes Sense

This option is not inferior; it is simply a different tool for a different purpose.

Consider MTM if:

- Your weight fluctuates frequently, making a significant investment risky.

- You need a reliable suit for a wedding or event in less than a month.

- You are building the foundation of a business wardrobe and need 3-4 suits for the price of one custom commission.

A high-quality MTM suit from a reputable mill (like Zegna or Loro Piana) is superior to 99% of what you will find in a department store.

When True Custom Is Worth It

You should consider the higher tier when you view your clothing as a long-term asset rather than a consumable good.

- The “Cost Per Wear” Equation: A $4,000 suit worn 150 times costs roughly $26 per wear. A $500 fused suit that loses its shape after 20 wears costs $25 per wear but looks worse every time.

- Professional Presence: For senior executives and business owners, the psychological boost of a garment that fits seamlessly can be a tangible competitive advantage.

- Hard-to-Fit Physiques: If you have athletic thighs, a significant drop, or uneven shoulders, the comfort of a custom pattern is unmatched.

The value here is longevity. You are paying for a garment constructed to be repaired, altered, and worn for twenty years.

A Note on Terminology

Many marketers have co-opted prestige terms to sell standard products. We see companies advertising “custom experiences” that are really just MTM with a glass of scotch.

True Savile Row-standard tailoring requires:

- A pattern drafted for an individual.

- Hand-cut cloth.

- A floating canvas.

- Multiple intermediate fittings.

If a brand promises a “custom” suit in two weeks without a basting stage, you are likely buying MTM. That is perfectly fine, provided you know what you are paying for.

Making Your Choice

The right decision depends on your timeline, budget, and physical requirements.

At Finch & Co., we specialize in bespoke suits because we know that for many clients, the “standard” simply isn’t good enough. When you wear a jacket that was engineered for your specific posture, the difference in confidence is immediate.

If you are tired of compromising on fit, schedule a consultation with us. We can walk you through the fabrics, show you the construction difference in person, and help you decide which path makes the most sense for your wardrobe goals.

David Finch

Master tailor with Savile Row training. David brings over a decade of bespoke craftsmanship to every garment.